Sustainable Precious Metal Recovery Guide

Did you know that more than $60 billion worth of precious metals are discarded each year in electronic waste alone? This staggering figure underlines the critical role of precious metal recycling. It’s not just good for our economy but also for the environment. By recycling metals like gold, silver, platinum, and palladium, we cut down on pollution and save natural resources.

Companies like Dongsheng Metal Trading are leading the charge towards sustainability. They make sure those precious metals get reused rather than landfilled. That precious metals recycling strategy underpins green recycling and long-term sustainability.

Principal Conclusions

- Each year, e-waste discards over $60 billion in precious metals.

- Recycling precious metals shrinks environmental harm and saves resources.

- Valuable metals include gold, silver, platinum, and palladium.

- Green recycling methods are essential for a sustainable future.

- Firms such as Dongsheng Metal Trading focus on precious metal recovery.

Exploring Precious Metals and Their Worth

Rare metallic elements known as precious metals attract both investors and manufacturers. Examples include gold, silver, platinum, and palladium, each prized for special traits. Notable traits are excellent conductivity, corrosion resistance, and rarity. Extracting and refining them uses up huge resources, so recycling becomes critical.

Market demand and each metal’s properties drive its value. Metal recycling ensures the supply chain remains robust. It lowers the ecological damage from mining. By thorough recycling, these metals return to their pure form. Such efforts save limited resources and create economic gains.

What are Precious Metals?

Unique features make precious metals ideal for many uses. Economic value stems from their scarcity and innate qualities. For example:

- Au: Prized for its shine and tarnish-proof nature.

- Silver: Celebrated for its adaptability and conductivity.

- Platinum: Esteemed for its toughness and catalyst role.

- Palladium: Increasingly popular in automotive and electronic applications.

Reasons to Recycle Precious Metals

The practice of recycling precious metals has emerged as a vital component for sustainability. It saves scarce materials and sharply cuts mining’s eco-footprint. Consider these advantages:

- Cutting down mining-related environmental harm.

- Using far less energy than fresh extraction.

- Contribution to a circular economy by reintroducing materials into production cycles.

- Economic upside from extracting high-value resources.

The Importance of Precious Metal Recycling

Recycling precious metals offers substantial environmental and economic benefits. Highlighting these advantages is key to reducing our ecological footprint. Additionally, it fuels market growth and resilience.

Eco Advantages

Green gains from metal recycling are huge. Retrieving metals from scrap and electronics reduces landfill load. It curbs mining demand and preserves nature.

This approach minimizes the harmful effects of mining, such as habitat destruction and pollution. Focusing on recycling precious metals helps us strive for a more sustainable future.

Economic Advantages

Financial perks of recycling are just as strong. Using reclaimed metals trims manufacturing budgets. It lets businesses choose reclaimed over freshly mined metals.

It spawns jobs in recovery plants and steadies markets as recycled-metal demand rises. By leveraging these economic advantages, businesses can improve their profitability. They add to a more sustainable marketplace.

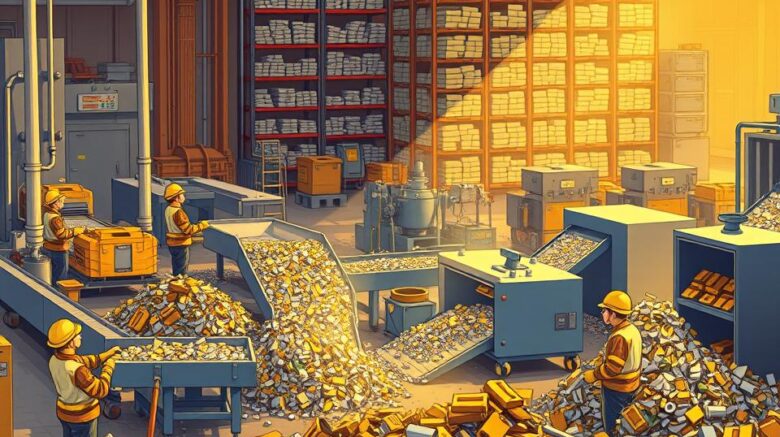

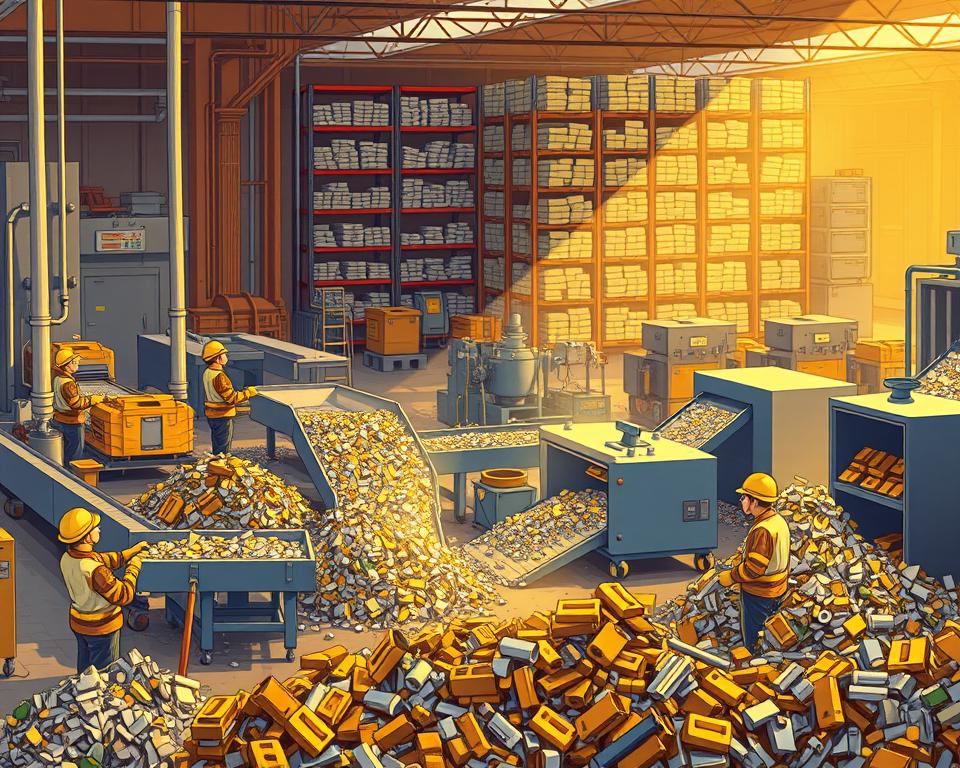

Steps in Metal Recycling

The precious metal recycling process is complex, involving several stages to ensure maximum efficiency. It starts with collecting metals from various sources like discarded electronics, jewelry, and industrial scraps. They are sorted, decontaminated, and analyzed to gauge composition and value.

Recovery Steps

A structured workflow is key to high-yield recovery. All stages focus on boosting metal yield. Sorting divides metals by kind and grade. Cleaning removes contaminants that could hinder recovery. Chemical analysis pinpoints metal levels to drive technique decisions.

Recycling Techniques Used

Advanced recycling techniques are employed to achieve high metal recovery rates. One method, thermal reduction, leverages heat to separate metals from base materials. Melting refines and aggregates metals, while wet chemical processes are used for delicate separations. Firms such as Dongsheng Metal Trading apply these techniques to raise recovery and profits.

Which Precious Metals Are Recyclable

Recovery efforts support both ecology and resource reclamation. A host of precious metals are recyclable, aiding markets and ecosystems. Awareness of recyclable metals guides consumers and companies.

Key Precious Metals

Gold, silver, and platinum stand out among precious metals. They’re found in jewelry, coins, and industrial uses. Gold’s high price and use make it a prime recycling target. Silver recovery matters too, thanks to its role in imaging, tech, and solar.

Though scarcer, platinum’s worth shines in auto catalysts.

E-Waste Metals

Electronic precious metals offer unique recycling chances. Devices such as phones and computers hold palladium and indium. Recovering such metals diminishes e-waste and yields vital materials.

Recycling these electronics metals is imperative. Industries aim to minimize waste and efficiently recycle resources.

Who Gains from Metal Recycling?

Recycling precious metals supports industries by providing efficient, green resource supply. Electronics, which embeds metals in gadgets, gains the most. The aerospace and medical fields use precious metals in essential applications. Examining industry recovery uncovers eco- and economic advantages.

E-Waste Sector

Electronics spearheads recovery, given the metal content in phones and PCs. Fast tech progress fuels growing e-waste volumes. Hence, recovering metals like gold, silver, and palladium is crucial. That saves resources and cuts mining carbon footprints.

Firms ramp up recycling to hit sustainability targets. Such a move upholds efforts to conserve and protect.

High-Tech Industries

Aerospace metal recycling is vital for the aerospace and medical industries, which rely on precious metals for critical components. High-performance alloys are essential for manufacturing flight parts and medical devices due to their durability and resistance to corrosion. Recovering them cuts costs and meets green regulations.

They recognize that recycling offsets material scarcity. And it improves operations, making metal recycling a smart green tactic.

How to Choose a Metal Recycler

Finding trustworthy precious metal recycling companies is key to recycling effectively. You should probe their procedures thoroughly. Their fees and techniques will shape your outcome. Service comparisons help you pick the best recycler.

What to Ask a Recycler

- Can you share your precious-metal recovery accreditations?

- What techniques do you use for each metal type?

- What yields can you deliver for gold, silver, and more?

- What is your pricing structure and are there extra charges?

- Can you provide references or testimonials from previous clients?

Evaluating Offers

When searching for a recycler, it’s vital to compare different companies based on their services. Create a table to compare key factors such as:

| Company Name | Recovery Rate (%) | Processing Fee ($) | Turnaround Time (Days) |

|---|---|---|---|

| Recycling Co. A | 95 | 50 | 7 |

| Recycling Co. B | 90 | 45 | 5 |

| Recycling Co. C | 92 | 55 | 10 |

Side-by-side comparisons help pinpoint the ideal recycler. This ensures you get the most value and meet industry standards.

Your Metal Recycling Handbook

Grasping recycler workflows is essential for metal recovery. These experts manage the entire process, from collection to processing. That approach drives top efficiency and returns.

How Recyclers Operate

Recyclers use advanced methods for metal recycling, including testing, separation, and refining. Collection comes from devices, jewelry, and industrial waste. Then, they use sophisticated techniques to separate different metals. Finally, they refine each batch to recover gold, silver, platinum, etc.

It optimizes yield while advancing environmental goals. It’s fundamental to building a sustainable future.

Finding Your Perfect Recycling Partner

Key criteria matter when choosing a recycler. Start with their sustainability track record. A focus on sustainability is non-negotiable. Also, examine if they handle everything or only certain stages.

Your budget will influence your choice. Gather price quotes for side-by-side comparisons. Firms such as Dongsheng Metal Trading tailor services to each sector. They stand out as dependable recyclers.

Pick the Right Facility

Recovery facilities are central to green waste solutions. Multiple types of facilities handle various recycling demands. Awareness of facility types guides you to proper recyclers. It aids companies and conserves nature.

Types of Facilities Available

Metal recycling facilities vary widely in their operations. Certain centers specialize in high-value metals; others take general scrap. Common examples include:

- General scrap yards handle both ferrous and non-ferrous materials.

- Precious Metal Recovery Companies: With a focus on high-value materials such as gold, silver, and platinum, these companies offer refined processing techniques.

- Electronics recyclers extract metals from old gadgets.

Choosing Facility Locations

Proximity to recyclers cuts logistical hurdles. Firms need to plan transport logistics. Here are some factors that influence access:

| Factor | Description |

|---|---|

| Proximity | Closer sites cut shipping costs and delays. |

| Partnerships | Connections with nearby facilities speed up recycling. |

| Service Range | Awareness of service menus aids in picking the right center. |

In sum, selecting the right type of recycling center and ensuring convenient access can significantly enhance the efficiency of metal recycling operations.

Recovering Metals from E-Waste

Electronic waste is a pressing issue in today’s world, causing environmental harm. Many e-waste items hold recoverable precious metals. It shows why we should treat e-waste as treasure.

How Electronics Contain Precious Metals

Devices often contain bits of gold, silver, and palladium. You’ll find them in components such as:

- Circuit boards

- Connectors and ports

- Capacitors and resistors

- Battery terminals

Common electronics conceal recoverable metals. With recycling, we can efficiently recover and reuse them.

E-Waste Recovery Benefits

E-waste recycling is vital for both environmental protection and resource recovery. It reduces landfill waste and saves natural resources. Key perks include:

- It minimizes environmental risks from improper disposal

- It cuts down on carbon emissions through eco-friendly practices

- It bolsters circular models by returning scrap to production

Encouraging electronic recycling promotes sustainable resource management. It lays the groundwork for a greener future.

Future Trends in Metal Recovery

Metal recycling is evolving, spurred by tech advances and green initiatives. Facing resource limits, recyclers embrace new methods. They are embracing new methods and processes, setting the stage for the future of recycling precious metals.

Trends in Sustainable Recycling

Modern green recycling strives to cut waste and eco-damage. Businesses adopt green packaging and energy-saving techniques. That evolution supports global green targets and fosters industry responsibility.

New Metal Recovery Tech

New methods in recovery enhance recycling performance. New technologies, such as automated sorting and hydrometallurgical extraction, enhance recovery rates. They ramp up yields and shrink eco-footprints, advancing metal recycling.

How to Start Your Own Precious Metal Recycling Business

Building a metal recycling enterprise calls for thorough planning and industry knowledge. Founders need a roadmap, regulatory know-how, and solid groundwork. That means in-depth market analysis and client identification. Securing licenses and legal compliance is crucial for long-term viability.

Steps to Establishing a Business

Setting up a precious metal recycling venture requires several essential steps:

- Analyze market demand and competitor landscape.

- Draft a strategy blueprint covering targets and methods.

- Acquire suitable recycling equipment that meets your operational needs.

- Obtain capital via loans or investors.

- Obtain vital permits and licenses for legal operation.

- Launch marketing to attract clientele.

Regulatory & Certification Needs

Understanding legal aspects when starting a precious metal recycling business is critical. Complying with eco-regulations keeps your business green and lawful. Key considerations include:

- Getting licensed by appropriate agencies.

- Complying with local, state, and federal regulations on waste disposal and recycling.

- Certifying employee knowledge of safety and handling rules.

As a Final Point

Recovering precious metals conserves resources and protects our planet. It helps people and companies cut waste’s ecological toll. Recovered metals curb mining and fuel green-job growth in recycling.

Metal recovery delivers both eco and economic upsides. Teaming with Dongsheng Metal Trading secures sustainable methods. Such alliances reinforce the circular economy for all stakeholders.

The journey to a sustainable future depends on collective action in recycling precious metals. Growing awareness can lead to a society that values responsible consumption and environmental care. Implementing these measures supports us today and safeguards future generations.